Kettle Project : The Market Teardown History Aesthetics Process Concepts Costing Induction

It's been a tiring week or two, but the results are in, and 48 kettles have been designed. This blog post is going to be a confusing mess of drawings and scribbles with, given my already compressed timescale, little commentary of note. This is exactly where the project should be, as we are at the peak of mess and confusion: the same things which we rely on to generate the ideas.

The focus here is to mix my 5 actual ideas and 3 generic templates with 6 different but related 'themes'. My aim is to put my brain into a complete mess and try to systematically generate constant random confusion, in the hopes that something decent will pop out from this process of cross-association. I have approached each 'Idea' in turn, but mixed up their general order and the order in which I approach each 'theme'. The order you read them in this post is the order they were conceived.

The design process is messy, and this post will show that, next weeks aim being to concentrate, organise and choose from the array of ideas in order to form a plan for something more concrete. This blog post is therefore rather tiresome, so for a quick look at all the ideas together and a conclusion, scroll right to the bottom of the post. Until then, here's an assault of different ideas in no particular logical progression.

Idea 1 : One Cup Measurement

The purpose of the 'One Cup' Idea was to communicate the users towards less water usage.

Taking the idea as just that, we come to our first theme for inspiration, 'Sharpness'.

The first idea comes out as a literal and visual interpretation of the criteria, basically realising more fully the initial idea sketch with a bit of an aesthetic twist.

We look to the next criteria, 'Manufacturing expression', or as I said in more depth in the before post, 'Reluctant acceptance of manufacturing processes'. I take this as a challenge to realise a new manufacturing process, and then make the design one that accepts it's limitations, and re-expresses them as visual impact. The result is a spun steel kettle; notice also the expressed draft angles on the injection moulded handle.

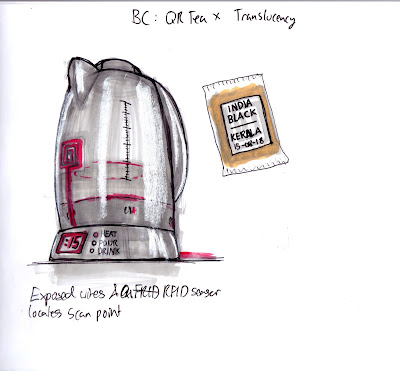

The next challenge, 'translucency' is here interpreted literally, producing a fully transparent kettle. The 'one cup' motivation here is the measuring system totally copied from OXO's measuring jugs. Copying is okay at this stage, the focus of which is to merely generate a lot of ideas.

'Use Expression' is a challenge to not only accept the use-requirements of the user, but make a big song-and-dance about it, in the same way that Richard Sapper's think-pads do, or, more constructively, instruments in a rocket ship or an aeroplane. Through exaggeration we of course make a tasteless and somewhat condescending visual statement, but it also challenges us to stretch the tactility and visuality of our user touch-points to the extreme.

Formal minimalism became one of my favourite challenges throughout this stage of the process. Here , I stretch the meaning of the 'Idea' to it's conceptual singularity, the result of which is sometimes entertaining, sometimes insightful but always interesting. It also it a very clear and coherent way of thinking about and expressing a single design idea, so this part always enhances my clarity.

'Helvetica and Monochrome' is a rather vague starting point, but I guess the general Idea is one that accepts the puritan Swiss/International style, so my aim with this theme has always to be to communicate in an international way, and provide 'just enough' visual detail to be functionally honest. Here, the 'interior' rings idea got me to think about a different way of moulding the kettle. Wether or not it is appropriate is a challenge for a more sincere stage in the design process.

The above shows the versatility of just one initial Idea, and how it can quickly become 6 different things. These then inspire new conceptions of how kettles can be manufactured (in addition to giving me more confidence with my drawing and using different materials). In the end, this shows that 'industrial design' is not merely a visual process, and it shows the benefits of re-iterating and cross-multiplying ideas.

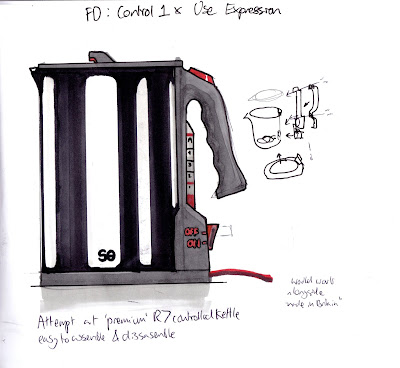

After dealing with a 'new' idea, I moved onto 'control 1', a pre-existing concept to ground myself in reality again and provide a different cognitive challenge.

Control 1 : Strix R7 controller.

As a reminder, control group 1 is based on the R7 controller and the general makeup of the wilko functional kettle I tore down a few weeks ago.

In this section, working on an existing concept has me thinking more exactly about specific details e.g part margins, material finishes, appropriate draft angels etc. which is an equally important challenge and one I believe should also be approached with creativity. I won't be commenting on each idea individually from here onwards, as doing so for 48 models is needlessly tiresome.

'Manufacturing Expression' has me exaggerating those draft angles I found earlier in the process which creates a dramatic effect.

Here, Minimalism has me twisting the brief to make a gun-like single element that can heat up any cup.

What we see then is mainly sensible ideas, with some moments of silly inspiration.

We return to a 'real' Idea next.

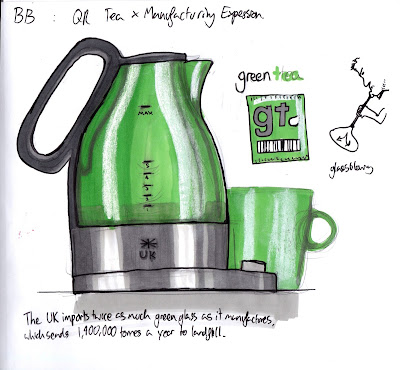

Idea 2: QR Tea

The purpose of QR Tea is to use embedded information on tea products to streamline the preperation and brewing process.

There are quite a few options already conceived in the sketch stage, so my job is to find space for these within 6 concepts, but also to accept any inspiration that comes separately.

We begin again with a literal and visual interpretation of the idea.

'Manufacturing expression' here had me investigating construction methods which led me to suggest using recycled wine-bottle glass. Going against the red aesthetic, although necessarily.

An assortment of Ideas then, and we then move onto another 'Idea'.

Idea 3 : Geyser Kettle

The geyser kettle heats and rises water into an upper compartment. So that water is boiled continually and can be stopped at once, which will perhaps be more convenient and will perhaps reduce energy usage.

Again we have a range of options here, with possible coffee attachments and different ways of separating the two compartments.

Here in 'CB' we have a design that will surely be dangerous, but it is one one hand expressive, and on the other could have more functional use as something for campers or the military. Maybe we can turn it upside down and use the bottom element as a stove too?

Here the 'formal minimalism' has helped us out by translating what by all appearances was a needlessly complicated solution into one which, though a bit of intelligent assistance, makes a reasonable stab at being a simple and proper solution.

Four down, four to go, we push on.

Control 2 - 360 cordless

Control 2 is all about the 360 base and cordless connector that we in the early 21st century all know and love.

A good opportunity to buy another new kettle.

Brand spanking new is this one. And we can compare it to the old alessi MG32 to find out what a difference 16 years and £130 makes.

Not much at all it seems. But we have now got an appreciation for the way these 'flat' systems work. Heat pipe comes in from the top, affixes to the bimetal and the switch, and is connected to the crescent-shaped element via a strix connector, flanked by two emergency contacts. Having liberated the family of their old kettle, we can be a little more adventurous.

Brand spanking new is this one. And we can compare it to the old alessi MG32 to find out what a difference 16 years and £130 makes.

Not much at all it seems. But we have now got an appreciation for the way these 'flat' systems work. Heat pipe comes in from the top, affixes to the bimetal and the switch, and is connected to the crescent-shaped element via a strix connector, flanked by two emergency contacts. Having liberated the family of their old kettle, we can be a little more adventurous.

This isn't even about learning anymore, I'm just destroying kettles for the fun of it.

Having been suitably inspired, it is time to move back to the design stage, This time I started from the back (from 'Helvetica'), because starting at 'sharpness' was getting repetitive and ended up with the same results.

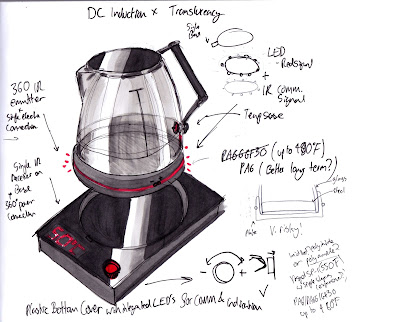

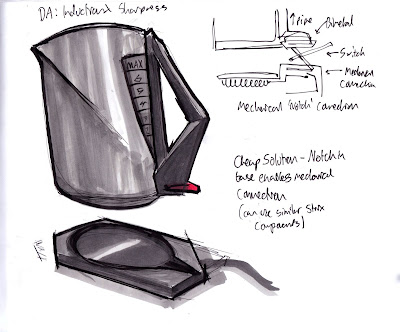

Idea 4: Induction Heating

The idea behind induction heating is that it we take the technology currently being used in hobs, which reduces mechanical complexity and exposed parts.

However, the USP, and the main problem, is that in order to be an effective replacement for the kettle, there should be an interface between the kettle and the hob in order to automatically boil water with no further user interface. The ideas that follow contain a wide range of different solutions to this problem.

Here we have gone for a kind of 'magsafe' connection.

Whereas minimalism forgoes the challenge entirely and becomes a 21st century camping set.

'Use Expression' attempts to work out volume via weight, which is interesting but could be fooled very easily.

Plastic on the bottom of a kettle? I'm trying to allow the user to place it on a surface, and to integrate communication in the base. But to work out what (if any) plastics are appropriate to sandwich between the base and hot metal will require some risky testing.

A satisfying wireless solution, but what kind of power can Seebeck generators produce?

The easy and cheap solution is to force the shape into a groove, but then what do we gain?

Control 3 - High Tech

'High tech' Kettles are among us now, although they are yet to gain control of the middle-market, if they were ever intended to.

In order to get a handle on the nature of the 'High Tech' kettle, I've had a look at one. (the pile of broken kettles grows)

I've got an AEG smart kettle too see if I can diagnose what's wrong with it and in any case, get a feel for this new paradigm of complexity in household appliances.

The bottom was a tough one to get open, 8 screws and two very strong snap fits sit in remarkable contrast to Wilko's 2 screws on the base of their £5 kettle.

Here are the brains of the operation, a PCB whose underside is littered with resistors, caps and tiny IC's. It is not my endeavour to understand this too fully at this stage, but we can get a good feel for how it does what it does by looking at the other side.

Given the complexity of the base, the kettle itself is dramatically spartan; in fact, the least complicated form of kettle i've seen so far.

So, besides the minutiae of the complicated internal circuitry, we know how it works. A bunch of beefy passive components filter the raw AC into the circuit board, which then controls the kettle via a relay.

A side objective was working out why it was broken, but unlike the Alessi, we see no clues in either the base, nor around the element of any dramatic electro-physical issues.

The fact that it does absolutely everything (including illuminate the parallel light) besides actually boiling leads me to believe it is an internal problem with the element. But suspicion surrounds the silent digital controller. Without a multimeter at home at this point, that's all I can say for now.

On with the design again, we look to consolidate in the variety of possibilities that the digital future promises us.

Aimed squarely at the middle-class. What more could one want than a rough cast kettle. How traditional!

Can one blow mould an electric kettle? I suppose with the right thickness of PP anything is possible, but the 'high tech' temperature measuring system and controls mean we can actually make a cheap and 'fun' solution out of them.

I am very sceptical of IoT technologies being shoe-horned into everything, but perhaps they are ore useful the simpler they are.

Idea 5 - dual mode nespresso machine

Handily, I already have a suitable test subject, which saves me trawling eBay.

As we can see it is impressively quick to produce a cup of water, but sadly not quite at an ideal temperature for tea. I am assuming this is not a critical problem, as a compromise could be reached by merely increasing the power sent to the heater or marginally reducing the flow rate of the water.

Other minor problems include the slight residue of coffee which is left in the water, which may require a separate water tube in some proposals.

Other minor problems include the slight residue of coffee which is left in the water, which may require a separate water tube in some proposals.

If you've not got a stupid idea every round then you're doing something wrong.

***

And so we have finished. A much more compelling and interesting account of this stage in the process can be found by arranging all the proposals into a table.

This way, we can see which tendencies run though each 'theme' and the commonalities between items of the same 'idea'. This will aid in moving forward, wether we chose to continue to explore a theme, run forward with one idea, or assemble new ideas from different parts; I might like idea AD, but prefer to see it explored in the minimalist style for example.

What I have hopefully proven here is the divorce that exists between 'ideas' and 'concepts' what you see is 48 concepts each worked from different sources. This is why it is important to continually engage creative and technical thinking at all points in the process, lest the original idea be muted by technical intrusion, or the visual representation of the idea take over from it's implementation.

***

I am generally pleased by the results I have garnered from this stage of the process. There are certainly a lot, and most of them are at some level of market-responsibility and functional practicality. Having said that, spending the best part of two weeks semi-carefully illustrating 48 concepts is not perhaps the most efficient use of time. Perhaps they would have been better kept at lower-resolution, or having not produced so many iterations. That, or a team who could bring their individual spin onto the concepts creating a more varied and less repetitive field of ideas.

I am however, at a point where a client or a manager could point at any one of them and say 'do it' and I could proceed with reasonable confidence; having already explored the technical limitations of many processes, the mechanical reality of existing concepts and the potential pitfalls and challenges of each individual concept. The next stage is to organise and select a tactical direction to take next.