Rendering is a very useful thing to carry out in the design process, and as tools make it quicker and easier to get good results, It may partially displace other methods of visualisation, giving the appearance of well-finished concepts in a very short time.

Especially in this current situation, when working from home makes physical visual prototyping difficult, digital methods may give both designers and engineers an edge when presenting their projects.

I have attempted to boil creating a quick but effective render into just two steps:

I have used fusion 360 for this post, but these steps will also work for SolidWorks Photoview and provide a good starting point for more advanced techniques in Keyshot. There are also a couple of bonus steps which will impress and make your product look closer to production than it really is!

This is by far and away the most helpful tip I learned following accounts like @renderweekly and @esbenoxholm. It seems like 80% of making a realistic render is done for you if you spend the time on making sure the model geometry is as detailed as possible. Two main things to look out for are:

Micro fillets - adding tiny 0.1 or 0.2mm fillets to every edge you can find on your model really makes the difference. This is a model of a shaver I made last year:

But if I revisit the model and take off just a few select fillets the overall impression is much reduced as surfaces look a lot flatter and fine reflections are not caught:

This can be the most annoying part of a design, like the time I had to select 153 edges around some text, but it can really help.

The second point is to add small gaps where they would be in real life. Most models made have tight fitting parts as they would hopefully do in reality. Pulling faces away from each other by a tiny amount under 1mm creates realistic shadow gaps. This mouse is a good example:

Lighting is a very important point, as the render is as much about what light hits the model as what comes into the 'camera'. Thankfully for this quick and easy guide, Fusion 360 when compared to Solidworks has some really good presets which make this step amazingly easy.

On fusion, the 'sharp highlights' scene, which seems to be set by default, is a godsend. It contains a couple of sharp light sources and moving the product into a 'confident' position seems to do about 90% of the job.

The next thing to give 30 seconds of attention to is the position tool on the scene settings tab. The position of the environment/lighting can make a massive difference to how the materials and surfaces are perceived, but spending a tiny amount of time getting it right will basically be the only scene input you need.

What holds Solidworks rendering back in my opinion is not that it is any better or worse, but its default lighting profiles, soft tent for example, are not the best. Photobooth style environments are useful, for example when planning to photoshop a model into context, but for showing a standalone product, they tend not to do justice to most of the geometry and materials. Look at the difference between a 'sharp highlights' and a 'photobooth' render on this glossy box.

And that's it! Focussing your energy on the model, and giving 30 seconds thought to positioning and lighting can get you a pretty impressive render most of the time. It's basically all I used in final year and we have Fusion 360 to thank for making it so easy. In addition, cloud rendering means that all this can be done (with a bit of patience) from something very small and slow, like my 2013 Macbook air.

Fusion 360 has some good materials as default and it's worth exploring the glossy plastics and metals which can look really good given the steps above. I have the carbon fibre plain material to thank for most of my final year project renderings- just drag and drop

Many of these designs featured use a good amount of lettering. One approach to applying lettering to a product is to use the decals function, which usually comes out quite well, and can add realism and interest to the image.

Another fancy way of adding realistic lettering (or any graphics) to a product is to customise a material and then apply it to a face. This can be done by exporting an image file from illustrator and applying it as the roughness for the material.

This gives a good effect, especially when used with the aforementioned sharp highlights, it just takes a bit of refinement in the scaling menu to get it in the right position. In general, an image with white or grey for the rough parts and black for the shiny parts is what is needed.

This can also be applied as a tiled graphic in order to create an interesting pattern similar to what can be achieved with injection moulding:

Hopefully these tips can help out, and get you designing and exploring more even though we are detached from our model making facilities! Just remember that a shiny render isn't the end of the process, it's just the beginning!

Especially in this current situation, when working from home makes physical visual prototyping difficult, digital methods may give both designers and engineers an edge when presenting their projects.

I have attempted to boil creating a quick but effective render into just two steps:

- It's all in the model - Tiny details in the model can make all the difference

- Lighting is key - Explore the default environments to pick out the important details

I have used fusion 360 for this post, but these steps will also work for SolidWorks Photoview and provide a good starting point for more advanced techniques in Keyshot. There are also a couple of bonus steps which will impress and make your product look closer to production than it really is!

It's all in the model - Tiny details in the model can make all the difference

This is by far and away the most helpful tip I learned following accounts like @renderweekly and @esbenoxholm. It seems like 80% of making a realistic render is done for you if you spend the time on making sure the model geometry is as detailed as possible. Two main things to look out for are:

Micro fillets - adding tiny 0.1 or 0.2mm fillets to every edge you can find on your model really makes the difference. This is a model of a shaver I made last year:

Fusion 360 render, sharp highlights, 500x500, 'final' quality

But if I revisit the model and take off just a few select fillets the overall impression is much reduced as surfaces look a lot flatter and fine reflections are not caught:

Previous model with 4 fillet features suppressed

This can be the most annoying part of a design, like the time I had to select 153 edges around some text, but it can really help.

Filleting around certain features can be time consuming, but gets you 80% of the way there.

Lighting is key - Explore the default environments to pick out the important details

Lighting is a very important point, as the render is as much about what light hits the model as what comes into the 'camera'. Thankfully for this quick and easy guide, Fusion 360 when compared to Solidworks has some really good presets which make this step amazingly easy.

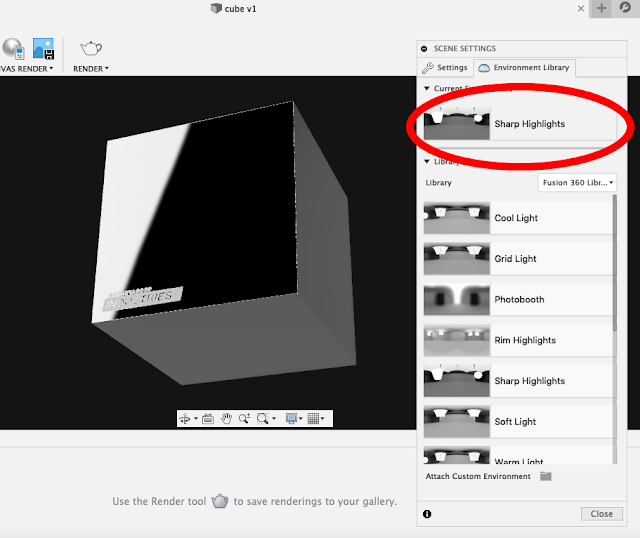

On fusion, the 'sharp highlights' scene, which seems to be set by default, is a godsend. It contains a couple of sharp light sources and moving the product into a 'confident' position seems to do about 90% of the job.

Sharp highlights is amazing, especially 2 hours before final hand in.

The next thing to give 30 seconds of attention to is the position tool on the scene settings tab. The position of the environment/lighting can make a massive difference to how the materials and surfaces are perceived, but spending a tiny amount of time getting it right will basically be the only scene input you need.

Environment position can have a dramatic effect on the appearance of your render.

What holds Solidworks rendering back in my opinion is not that it is any better or worse, but its default lighting profiles, soft tent for example, are not the best. Photobooth style environments are useful, for example when planning to photoshop a model into context, but for showing a standalone product, they tend not to do justice to most of the geometry and materials. Look at the difference between a 'sharp highlights' and a 'photobooth' render on this glossy box.

Black cube, Stainless Steel - Polished, Sharp Highlights

Black cube, Stainless Steel - Polished, Photobooth

And that's it! Focussing your energy on the model, and giving 30 seconds thought to positioning and lighting can get you a pretty impressive render most of the time. It's basically all I used in final year and we have Fusion 360 to thank for making it so easy. In addition, cloud rendering means that all this can be done (with a bit of patience) from something very small and slow, like my 2013 Macbook air.

Bonus features

Materials

Fusion 360 has some good materials as default and it's worth exploring the glossy plastics and metals which can look really good given the steps above. I have the carbon fibre plain material to thank for most of my final year project renderings- just drag and drop

Fusion 360 render of my Hyperloop Chair Final Year Project

Decals and logos

Many of these designs featured use a good amount of lettering. One approach to applying lettering to a product is to use the decals function, which usually comes out quite well, and can add realism and interest to the image.

Applying a decal to a model in Fusion 360

Another fancy way of adding realistic lettering (or any graphics) to a product is to customise a material and then apply it to a face. This can be done by exporting an image file from illustrator and applying it as the roughness for the material.

Applying a pattern to a material to use as a logo

This gives a good effect, especially when used with the aforementioned sharp highlights, it just takes a bit of refinement in the scaling menu to get it in the right position. In general, an image with white or grey for the rough parts and black for the shiny parts is what is needed.

This can also be applied as a tiled graphic in order to create an interesting pattern similar to what can be achieved with injection moulding:

Hopefully these tips can help out, and get you designing and exploring more even though we are detached from our model making facilities! Just remember that a shiny render isn't the end of the process, it's just the beginning!